Maybe We've All Seen Too Many Movies

Sci-Fi tales got us dreaming.

Now it's time for nuts and bolts.

|

| Probably not like this -- at least for a while.[image] |

Yes, the Earthlings are, actually, this close to "taking humanity's great first step" -- the largest "first step" we've ever taken.

NASA is unquestionably preparing to get serious with plans for inhabiting Mars. They even conducted a contest soliciting ideas from ordinary citizens which might be useful in "keeping the Mars astronauts safe."

Naturally, this little blog was anxious to "jump right into the competition."

All these suggestion will be listed by number, but even before we begin the list, here are a couple of suggestion which aren't particularly about the "Martian-side" of things.

Notably, Earth men living on Mars are not, actually, "astronauts." They were "astronauts" while they were on their way to Mars, but once having arrived there, they're going to have to have a new description.

Notably, Earth men living on Mars are not, actually, "astronauts." They were "astronauts" while they were on their way to Mars, but once having arrived there, they're going to have to have a new description.

Also, forget the "keeping safe" idea. Mars isn't going to be a convincingly safe place for Earthly types for years. In fact, since a "disaster" on Mars could conceivably detour the entire project for decades, it will be important to not promote the idea that habitation is anything similar to a "sure fire" expedition, It will also be important to tailor design suggestions about Mars habitation with as much redundancy as reasonable to give those who go and the entire mission the best chances possible for success.

The highest priority for keeping the astronauts "safe" is to create the highest degree of independent life support sustainability as possible. These suggestions target that goal.

The highest priority for keeping the astronauts "safe" is to create the highest degree of independent life support sustainability as possible. These suggestions target that goal.

Although no one has much experience about Martian designs, MeanMesa can offer a few decades of experience in engineering for Arctic designs. While the "cold" on Mars is quite beyond the "cold" encountered in the oil field at Prudhoe Bay, Alaska, [400 miles north of the Arctic Circle], a few of the same design considerations may be helpful.

With this said, let's look at some suggestions. When the harsh Martian environment offers an actual advantage to some part of this, we'll be sure to note it.

1. Everything In Pairs

All the life support equipment which will be sent to support the Mars mission needs to be in pairs -- two of everything. Think of this as a plan to establish an "alpha camp" and a "beta camp," copies of each other and each one equipped to sustain life.

This approach will offer dividends in the future even if nothing occurs to send astronauts from one to the other. For one thing, having two complete camps will allow safe opportunities to test modifications and other changes in the future. Later, when it's time to increase the human presence on Mars, most of the equipment required for a start will already be there and operating.

One of the most serious "threats" to habitation will be from micro-meteor bombardment through Mars' near vacuum atmosphere. Two separated camps will limit the likelihood of meteor damage to both.

2. We'll Need a Reactor

By this, we're talking about a new type of reactor. Humans have already developed gigantic reactors to provide electricity to cities and tiny [unshielded] reactors to provide electricity to space probes. Mars habitation will require one sized in between -- perhaps around the size of a residential refrigerator.

All reactors "come with baggage," but a reactor suitable for Martian service has different "baggage" than one designed for Earth service. Some of the most obvious of the "different" challenges emerge right away. There is not going to be any surplus water on Mars for quite some time, and typical Earth bound reactors gobble up water for cooling, spent fuel storage and heat exchange like drunken sailors.

The size and capacity of a Martian reactor will also require some specific design. The habitat power system will need to be much larger than the tiny reactors which have been built into space probes, but for many other reasons, much smaller and more compact than the gigantic plants dotting the coastline in California. The reactors designed for nuclear submarines will probably be more similar in size, but a different process will be required for Martian service.

From the choices currently available in Earth bound reactor technology, a molten salt thorium process offers many compelling design advantages. This design was actually developed years ago on Earth, but competing processes became the norm leading to the adoption of the reactors in service today.

Reactors using the MSR process [shown at left] could meet many of the restraints inherent in the Mars project. [Read more about molten salt, thorium reactors here_CEN]

All reactors "come with baggage," but a reactor suitable for Martian service has different "baggage" than one designed for Earth service. Some of the most obvious of the "different" challenges emerge right away. There is not going to be any surplus water on Mars for quite some time, and typical Earth bound reactors gobble up water for cooling, spent fuel storage and heat exchange like drunken sailors.

The size and capacity of a Martian reactor will also require some specific design. The habitat power system will need to be much larger than the tiny reactors which have been built into space probes, but for many other reasons, much smaller and more compact than the gigantic plants dotting the coastline in California. The reactors designed for nuclear submarines will probably be more similar in size, but a different process will be required for Martian service.

|

| Low pressure thorium, molten salt reactor [diagram] |

Reactors using the MSR process [shown at left] could meet many of the restraints inherent in the Mars project. [Read more about molten salt, thorium reactors here_CEN]

We can consider this very preliminary idea of the basic operational requirements for electricity and heat. Although quite conceptual, the diagram illustrates a few "multiple constraint" issues but it also illustrates some "environmental opportunities." The best way to communicate all of this is "by the numbers."

1. Reactor

The reactor's single mission is to provide a constant supply of heat. Mars is cold, and it is far enough away from the sun to limit the amount of electricity which can be generated by solar panels. This was enough to power a rover, but a human habitat will require substantially more. A properly designed "pocket reactor" would offer more dependability while representing a lower transportation mass than the number of photoelectric panels required to do the same job.

Take a look at the following diagram.

Take a look at the following diagram.

The heat exchangers would receive heat energy from the reactor via a molten stream conceivably propelled by "field stator" induced charge. Steam or fluid heat transfer plans would have too much additional "baggage" thanks to the temperature and the availability of water. Obviously, cooling water could not be a required commodity for reactor operation. The actual material finally selected to move reactor heat to the various heat exchangers will require materials development to accommodate dependability and efficiency requirements. [Existing two phase reactor heat transfer designs are close, but still not ready for Mars use.]

|

| [diagram MeanMesa] |

While the area [orange] would be a logical limit for reactor encasement, other parts of this process system could be included in the reactor module based on the size of transport module required. This is the area which would require radiation shielding.

The shielding requirements would not be nearly as rigid as the ones imposed on Earth reactor designs. Chart elements 8, 9, 10 and 11 would necessarily be located close to the habitat, but all the rest could be located remotely -- either integrated into the reactor module itself or adjacent to it. There would be two gas lines [O and H] and an insulated [heat traced] water pipe to storage units, but all the other connections to the habitat would be electrical conductors.

2. Reactor Module Environmental Heat Exchanger

This would maintain heat for the environment immediately around the reactor's exterior. If the interior temperature of the reactor module were simply allowed to settle at Mars surface temperature of -200 F, the cold could complicate the delivery of the heat exchanger streams. It is likely that the reactor would need to be operating at a minimum level of heat generation when being launched and during the long trip to Mars orbit in order to prevent the heat exchanger streams from solidifying before becoming operational on the Martian surface.

If the reactor's transport module design turns out to require a heated environment in space, this heat exchanger would accommodate that.

3. Generator Heat Exchanger, and

4. Stirling Generator Set

These items are combined for a reason which has more to do with the idea of using a Stirling generator than with the reactor process itself.

The original concept for a Stirling "air engine" is from the last century. When it was first proposed and tested, the design had some "non-recoverable" defects: a. the necessary materials were not available, and b. steam engines were just becoming popular. Today, NASA should have little trouble developing materials for the Martian environment and for a "Stirling-type" generator motor, and on a planet where producing every ounce of liquid water will require significant work, steam engines are not particular attractive as design alternatives.

Martian Environmental Design Advantage:

Low Temperatures on Martian Surface

On the other hand, this may be one of those opportunities to use the Martian environment as a design advantage. A Stirling engine is powered by an available heat differential. Using the reactor heat to provide the "hot side," when first designed an "Earthly limit" was imposed by the availability of a "heat sink" cold enough to sustain the necessary temperature differential.

Mars' -200 F environment offers a "heat sink" of extra-planetary potency!

|

| Stirling Engine Diagram [image] |

Further, the pocket reactor offers a "heat source" generous enough that not even a rather "sloppy" Stirling-style engine's single use "waste" would present much of a problem in terms of energy conservation. Raising the local Martian surface temperature by a few degrees Fahrenheit as a result of running such an engine would make very little difference -- even over an extended period.

The design challenge is centered on the apparatus at the top of the diagram, but it is not an insurmountable challenge. Even considering the various inefficiencies, the "trade-off" is quite attractive.

Finally, a Stirling engine requires a gas body inside the cylinders which can be sequentially heated and cooled. Reviewing the diagram, there are a few choices. Although nitrogen or carbon dioxide are available, these would have to be extracted from the Martian atmosphere. The other choice seems to be using the hydrogen gas being generated by the electrolysis process. [Hydrogen is not explosive in an atmosphere where there is almost no oxygen.]

While the diagram only mentions "generator set," the "generator" part will also be a design challenge. If the Stirling and its heat exchanger are located within the heated environment of the reactor module, the generator design becomes a little simpler. In this case a more or less standard design generator -- probably incorporating special low temperature and wear resistant metals -- should be able to function quite reliably on Mars.

5. Electric Ice Drill

Because any concept of Martian habitation requires a reliable source of water ice, the camps will necessarily be located where ice is readily available. This part of the plan will be left to the orbital satellite observers and their conclusions, but the positive side is that the rovers have already "detected" traces of water ice below the surface in a number of places.

For human habitation these "detected trace" ice quantities will, of course, be quite insufficient. The camps have to be sited in locations where sub-surface ice deposits are the robust equivalent of "proven reserves" as the oil hungry Earthlings speak of them. Everything depends on this, and it may well require that these first habitats be placed on Mars' polar regions where water ice may be more abundant and closer to the surface. [Actually, everything depends on everything, but this isn't news. However, this is why the expense of "double everything" can be justified. We don't need to be trying to inhabit another planet "on the cheap."]

Martian Environmental Design Advantage:

Sub-Surface Ice Deposits

With sufficient electrical generation an effective ice drill becomes feasible. This would be one heavy motor -- designed with low temp metals -- which couldn't really be replaced by a lighter weight alternative. On the bright side, there is almost certainly good access to significant water ice within a few feet of the Martian surface -- especially at the poles.

Ice drilling holds the same uncertainties on Mars as similar processes hold on Earth. If the drill encounters a "rocky bottom" to the ice deposit first selected, it must be moved -- by astronauts -- but not necessarily very far, perhaps no more than a few yards. The drilling prospects might change considerably at another location close to the first. The chart's use of the term "liquefaction" suggests that the "material returned" from ice drilling may have a high percentage content of soil or gravel. It will almost certainly need to be heated to a state of "slurry" before any further processes can begin.

On the other hand if one of the drilling sites proves very positive and the ice returned is relatively clean, the drilling operation at that site might, at some later point, be replaced by a reactor driven "heat wand" which could simply liquefy the ice enough to retrieve it for hydrolysis and water supply. [Note: The water being produced at lower right of this diagram is the feed water shown on subsequent diagrams.]

6. Ice Liquefaction Heat Exchanger, and

7. Hydrolysis Plant

and

9. And 10. The Gas Storage Tanks

Flow controls on any of the elements of the reactor's stream heat exchanger feeds [Stirling generator, ice liquefaction or reactor module environmental heat radiator] may be testy. What is proposed here is basically no flow control valves beyond an emergency shut off. The difficulty will arise from the reactor flow cooling to a solid state. This means that both the generator set exchanger and the ice liquefaction process exchanger must be calibrated to proceed essentially autonomously for as long as the reactor is capable of producing heat.

With respect to the ice liquefaction process, this will require either a suitably sized slurry retention tank which is large enough to continue to provide water the the rest of the process even if the ice drill has to be shut down and moved.

Further, there will need to be a staged water purification process either before hydrolysis or, at least, before potable water production. Hydrolysis will not require entirely purified water, but it will require water with most particulates and sediments removed. There is no requirement for duplicated water purification. Preliminary purification can feed both hydrolysis and then go on to secondary purification in route to potable water storage.

Martian Environmental Design Advantage:

Low Atmospheric Pressure & Cold Ambient Temperature

The volumes of oxygen and hydrogen gas produced by hydrolysis will need to be compressed prior to entering the gas storage tanks, but a low ambient temperature will make gas storage less energy intensive. The low atmospheric pressure will increase the efficiency of the hydrolysis. Both storage tanks will need to be constructed to hold a pressure differential generally higher than what is required in Earth atmosphere, but -- on the plus side -- tank size will not matter much. These storage tanks could be very large containers which are inflated by the entrance of the hydrolysis gases. Redundancy suggests a number of such tanks, but flow control valving in the gas feed distribution piping should not be difficult. [Pressure gauges for the storage tanks might be a little more complicated.]

The Martian Version of a Hydrogen Fuel Cell

The hydrogen generated in hydrolysis suddenly has very limited usefulness in an environment which provides essentially no oxygen. However, there may be a solution to this. The fact that hydrolysis is energy intensive is justified by the production of the oxygen, but part of that "expense" is also retained in the hydrogen produced.

With hydrolysis operating at a significant production level, some of the gasses produced might be stored in the Martian equivalent of a hydrogen fuel cell. Naturally, such a fuel cell would have to supply its own oxygen, but if oxygen were plentiful, making fuel cells containing both oxygen and hydrogen might make sense. Storing a good number of these fully charged fuel cells would give the advantage of 1. using the oxygen in them for breathing if necessary, and 2. essentially creating the equivalent of "batteries" which could provide some of the electrical energy previously consumed in the hydrolysis if there were an emergency.

8. Potable Water Storage

There is no telling what might be found in Martian "ice water" when the need arises to actually drink some. There is very little possibility that such water might be contaminated by any of the pollutants [created by intelligent creatures] typically ruining water on Earth, and there is, likewise, little chance that Martian "ice water" would suffer from organic Earth-style problems such as eutrophication.

However, the water's chemical content might be "off the chart." Worse, some of those chemicals might be quite unsuspected, dangerous to humans, hard to detect or difficult to remove. If this turns out to be the case, the Martian "ice water" will need to be distilled. If distillation is required, essential ions, minerals and electrolytes required for humans will be have to be added before it can be used, and those will probably need to come from the "home planet." [Try to imagine a country western song about crewing on a space ship making a salt run to Mars...]

Of course, a water storage tank will require some serious insulation and a continuous heat trace. Additionally, these suggestions would be quite incomplete if they didn't include a hydroponic green house. This water business is serious.

11. Habitat Electrical and Heat

We can dismiss the idea of a reactor driven heat exchanger to provide habitat heat because of the complications inherent in such a plan. Further, it would be a good design feature to separate the habitat quarters from the reactor/ice drilling/hydrolysis mechanics anyway. Running insulated electrical conductors and insulated, heat traced pipe to service the habitat makes sense.

Having a dependable, plentiful supply of electricity is also serious business. The fuel cells might also come in very handy if they're needed. [They should theoretically also be able to be used to "make water" since the essential components are right there.]

These suggestion include a little more about habitat construction, but power, heat and lights will be a good start.

3. Making the Transportation Problem Easier

The last complex rover landing was, indeed, both inspirational and hair raising. However, Mars habitation is going to take lots of equipment and lots of trips from the Earth to Mars. By "lots" we should assume something in the range of 50 to 100 heavy lift launch payloads. The entire enterprise needs to be consolidated into something like its own "single purpose agency" as a "wing" of NASA. The scope, complexity and intricacies of establishing a functioning habitat on Mars could, otherwise, bury the very legitimate work and responsibilities of NASA which is responsible for accomplishing "other" science priorities at the same time.

Once the "list" on everything that will need to be sent to Mars begins to fill out, the scope of work will also start to become clear. The current model is to conduct serious preparation for a launch project for a long time, culminating on some sunny morning at Cape Canaveral. The Mars project will present a much more "production oriented" attitude resembling an assembly line approach.

The Mars Train: The 500 day transit window will become a picture of an interplanetary train with payloads spaced out all along the way and arriving at Mars like a regularly scheduled prelude to an invasion. There is simply too much to do for the project to go in "fits and spurts." MeanMesa is also concerned about the likely problems with fickle Congressional financing.

Streamlining the Run to Low Earth Orbit: There will not be many considerations about specific payloads which will particularly differ much. The task of lifting these packages to LEO can be streamlined, and the per ton costs reduced with a little practice. We can expect improvements in technology to be appearing all along the way.

Streamlining the Trip to Mars: It makes good sense to consider the "long leg" of the trip as separate from the "lift off leg." The separate tasks of targeting and accelerating orbital payloads is far more manageable when handled alone than lumping everything together and tasking lift off rockets with the whole work. Something akin to a "space tug boat" will be need for this work. [Make two of them...and, don't forget that we'll need a gas truck.] It can pick up payloads in LEO, fine tune the trajectory and accelerate them in space instead of battling Earth's gravity and then accelerating them in space.

NASA has collected a very enviable think tank of innovative problem solvers capable of inventing their way through really complicated project requirements, and this should be at the disposal of the Mars group. Just as the MSR-thorium reactor and the Stirling Heat Engine generator sets are based on research from years ago, the task of moving a significant number of payloads to our neighboring planet might also benefit from an old design, in this case, the nuclear propulsion concepts of the old Orion Project.

The Orion Project proposed using small atomic explosions to provide the thrust needed for launching space craft. Don't groan. The idea actually had a number of very attractive advantages, but the 1963 Atmospheric Test Ban Treaty prohibited such nuclear explosions. [Read more about the treaty here 1963 Test Ban Treaty-US State Dept] The Treaty was a good idea at the time because we were rapidly introducing so much radiation into the planet's atmosphere.

Nonetheless, it may have turned out to be a case of "throwing the baby out with the bath water." MeanMesa is proposing it again here because if it were used to propel payloads to a Mars habitat, the nuclear explosions would be occurring much farther away from our planet. The additional fact that the payload shipments would be unmanned makes the idea even more appealing -- the bursts of thrust ["G's"] developed by such propellant systems would be brutal, but the transit velocities would be exceptionally high. [For visitors unfamiliar with the basic concept of the Orion propulsion design, here is a video of some of the "proof of concept" testing done in the 1950's. Project Orion SPACE.com]

NASA has collected a very enviable think tank of innovative problem solvers capable of inventing their way through really complicated project requirements, and this should be at the disposal of the Mars group. Just as the MSR-thorium reactor and the Stirling Heat Engine generator sets are based on research from years ago, the task of moving a significant number of payloads to our neighboring planet might also benefit from an old design, in this case, the nuclear propulsion concepts of the old Orion Project.

|

| A nuclear "locomotive for the Mars train" [Orion WIKI] |

Nonetheless, it may have turned out to be a case of "throwing the baby out with the bath water." MeanMesa is proposing it again here because if it were used to propel payloads to a Mars habitat, the nuclear explosions would be occurring much farther away from our planet. The additional fact that the payload shipments would be unmanned makes the idea even more appealing -- the bursts of thrust ["G's"] developed by such propellant systems would be brutal, but the transit velocities would be exceptionally high. [For visitors unfamiliar with the basic concept of the Orion propulsion design, here is a video of some of the "proof of concept" testing done in the 1950's. Project Orion SPACE.com]

The Mars Orbital Warehouse Crew: With payload packages arriving in Mars orbit every week, each one needing to be "landed" with a very close accuracy on targets [alpha and beta camps] on the Martian surface, there is a definite need for a crew orbiting Mars to "handle the details." This looks like it might require "the other space tug" plus a really scaled down version of the ISS to handle crew quarters, planning and communications, etc.

A good portion of the equipment can be positioned and landed before astronauts arrive. The orbital Mars station will also be a good place to prepare astronauts -- even long before the permanent descent. A crew of three or four along with two or three astronauts could handle this work.

A good portion of the equipment can be positioned and landed before astronauts arrive. The orbital Mars station will also be a good place to prepare astronauts -- even long before the permanent descent. A crew of three or four along with two or three astronauts could handle this work.

The Mars Orbit to Surface Run: There HAS to be a better way than dangling a payload by a cable and firing retro rockets! MeanMesa was, just like most other observers, dangling on the edge of his chair while watching the latest rover landing strategy unfold. Although successful, it was a hair raising, Rube Goldberg thriller!

Martian Environmental Design Advantage:

Low Planetary Gravity and Low Atmospheric Density

Low Planetary Gravity and Low Atmospheric Density

The low Martian orbital escape velocity should make not only accurately placing the payload packages more successful, but also it should offer an opportunity for astronauts to visit the camps before committing to a more permanent residence. This one is a problem perfectly prepared for NASA propulsion and guidance experts, so we can leave it there.

Still, some sort of shuttle vehicle is going to be needed for the leg from Mars orbit to the surface. Although the invitation to enter the contest specifically discouraged "un-workable" suggestions, there have been plenty of enticing "un-workable" suggestions already made: the orbital ring, the space tether and the space elevator to name a few. Each of these become slightly less "un-workable" given the specific planetary physics of Mars compared to those of Earth.

In fact, materials and rocket technology has been improving annually since most of them were first categorized as "un-workable."

Maximizing Utility of Payload Containers: Naturally, all the payload containers will need to be standardized as much as possible. Payload weights will also need to be standardized. This will allow the design for each phase of the trip to also become much more standardized, too. Further, this really doesn't mean giant payloads -- it means lots of payloads which are the same size and roughly the same weight.

Also, these payload containers will ultimately be on the ground on Mars. The standard design should encompass every possible feature which can even possibly be used in the camp structures later. Reusing payloads fundamentally expands the "cost benefit" calculation for the whole mission.

- air locks built into both ends

- radiation shielding -- even just weight efficient partial shielding

- heavy insulation for Martian temperatures

- design accommodations for the containers to be joined or modified once on Mars

- repair ability -- for patching if needed

- pre-manufactured access for habitat utilities

- design considerations to make them movable once they are landed

Equipment like the reactor and generator set, the ice drilling equipment and the various storage tanks can all land as individual payload containers, but this also makes being able to move them around, at least a little ways, important. They will have to be organized and connected to each other for both astronaut access and piping and wiring, and this will probably require more control for placement than can be expected from the maneuvering capability of a loaded "space tug" hauling them down from Mars orbit.

This will require a "surface tugger" with enough power and traction to drag one of these payload containers a few feet into place. This can be a multi-use vehicle, and it might be simpler if it were powered by a fuel cell. The same vehicle might also be needed to level a site before placing the containers in a camp site.

Don't forget to also pack a good long pry bar and a "come-along" made from low temp steel! There will be some of this which is destined to be common labor even if it is hard to think about performing manual work in a space suit.

This will require a "surface tugger" with enough power and traction to drag one of these payload containers a few feet into place. This can be a multi-use vehicle, and it might be simpler if it were powered by a fuel cell. The same vehicle might also be needed to level a site before placing the containers in a camp site.

Don't forget to also pack a good long pry bar and a "come-along" made from low temp steel! There will be some of this which is destined to be common labor even if it is hard to think about performing manual work in a space suit.

4. A Few Habitat Ideas

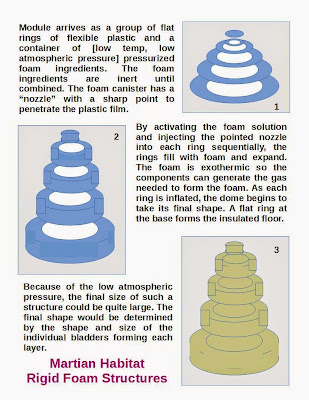

For Arctic applications, polyurethane foam is widely used to control thermal migration. The foam is provided in pressurized cans, is exothermic and becomes quite structurally rigid after it is applied. The foam expands by forming a gas which fills the voids in the foam's polyurethane.

The polyurethane idea would have to be modified chemically to function in a similar way in Martian temperatures -- for example, the exothermic rate of the reaction causing the gas creation mix would have to be "heated up."

Also, when applied in Earth's atmospheric pressure, the foam's expansion reaches a "balance point" and stops expanding. On Mars the foam idea can only work when the foam is released into a closed, flexible containment, otherwise, it would continue to expand almost without limit, forming an unusable structure which would not take a usable form or be structurally rigid,

The usable flexibility of the material forming the bladders could benefit from the temporary heating caused as the foam reaction takes place to generate the gas. the NASA materials innovation department has to take this from here.

The foam structures created this way could be large enough when combined to form a sizable habitat structure. They would "join" relatively easily -- possibly with the application of the same kind of foam at unions to create air containment. Insulation thickness would be determined by the shape of the bladders when they were manufactured. For example, a structure large enough to provide space for a functioning hydroponic garden could be fabricated in this manner.

Adding any kind of "sprayed on" coating to the outside of the foam structures would be a problem. However, thin sheets of material to repel dust abrasion in wind storms, add radiation protection [foil] or even flexible photo-voltaic material such as the recently developed fabric form could be applied by men wearing spacesuits.

Also, these foam structures, once the foam is fully rigid, could be cut open in order to join them to other foam structures or payload containers.

Also, payload containers with air locks already manufactured into both of their ends could be joined

to the foam structures very effectively. The foam could also be used to repair micro-meteor penetrations in either the foam structures or the payload containers.

Insulated windows for installation into the foam structures would be too heavy to justify the cost of their transportation, but they could be built into the payload containers at the time of manufacture.

Constructing a Martian base camp something like the fictional picture [above] might actually be significantly easier that one first thought. After taking only a glimpse of the art work, and considering the estimates and suggestions made in this proposal, the 50 to 100 payloads of equipment begins to appear quite reasonable. Although things may at first seem very primitive, as the mission goes along, good ideas will begin changing and improving everything in no time.

There will be a following post on this same topic which provides more details about designing the Martian habitat. If this is "piquing" your interest, please drop into Short Current Essays in a day or two.

Thanks for visiting!

The polyurethane idea would have to be modified chemically to function in a similar way in Martian temperatures -- for example, the exothermic rate of the reaction causing the gas creation mix would have to be "heated up."

Also, when applied in Earth's atmospheric pressure, the foam's expansion reaches a "balance point" and stops expanding. On Mars the foam idea can only work when the foam is released into a closed, flexible containment, otherwise, it would continue to expand almost without limit, forming an unusable structure which would not take a usable form or be structurally rigid,

The usable flexibility of the material forming the bladders could benefit from the temporary heating caused as the foam reaction takes place to generate the gas. the NASA materials innovation department has to take this from here.

The foam structures created this way could be large enough when combined to form a sizable habitat structure. They would "join" relatively easily -- possibly with the application of the same kind of foam at unions to create air containment. Insulation thickness would be determined by the shape of the bladders when they were manufactured. For example, a structure large enough to provide space for a functioning hydroponic garden could be fabricated in this manner.

Adding any kind of "sprayed on" coating to the outside of the foam structures would be a problem. However, thin sheets of material to repel dust abrasion in wind storms, add radiation protection [foil] or even flexible photo-voltaic material such as the recently developed fabric form could be applied by men wearing spacesuits.

Also, these foam structures, once the foam is fully rigid, could be cut open in order to join them to other foam structures or payload containers.

Also, payload containers with air locks already manufactured into both of their ends could be joined

|

| Mars settlement. [image] |

Insulated windows for installation into the foam structures would be too heavy to justify the cost of their transportation, but they could be built into the payload containers at the time of manufacture.

Constructing a Martian base camp something like the fictional picture [above] might actually be significantly easier that one first thought. After taking only a glimpse of the art work, and considering the estimates and suggestions made in this proposal, the 50 to 100 payloads of equipment begins to appear quite reasonable. Although things may at first seem very primitive, as the mission goes along, good ideas will begin changing and improving everything in no time.

There will be a following post on this same topic which provides more details about designing the Martian habitat. If this is "piquing" your interest, please drop into Short Current Essays in a day or two.

Thanks for visiting!

No comments:

Post a Comment